Dr. Helmut Riedl from TU Wien is going to talk on December 16, 2021 in the frame of IGK within the SFB-TR 87 on Thursday, December 16th, 2021, 10:00 h – 12:00 h, at Materials Chemistry in Aachen.

Part I: Durability of physical vapor deposited CrN based coatings – Insights on fracture and fatigue mechanisms

Tailoring the intrinsic fracture characteristics of hard protective coatings towards the fatigue proper-ties of state-of-the-art bulk materials is paramount for extending the fatigue-life of coated compo-nents. Thus, an in-depth knowledge on the failure pathways of ceramic-based thin films – typically lacking in intrinsic ductility – but also coated components under cyclic loading is imperative to extend their lifetime. Within this seminar, I want to discuss novel approaches in the field of fatigue testing of thin films on the example of dc magnetron sputtered as well as cathodic arc evaporated CrN.

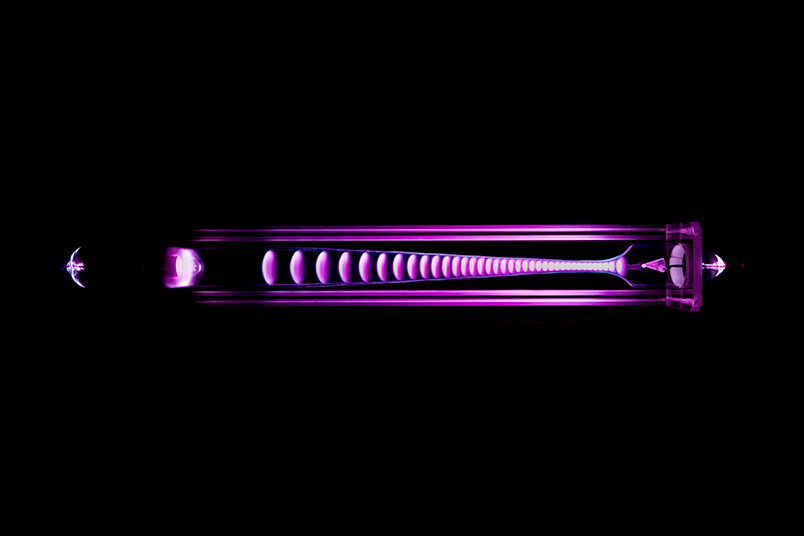

In detail, to reveal the intrinsic fracture toughness (KIC) and critical failure aspects of thin films under various loading conditions quasi-static and cyclic bending of pre-notched, unstrained micro-cantilever beams in conjunction with in-situ synchrotron X-ray diffraction have been performed. Up to the high-cycle fatigue regime (i.e., N = 107 cycles), the failure of CrN coatings is shown to be dominated by the inherent fracture resistance instead of well-described fatigue phenomena, with further correlations drawn to apparent growth irregularities (i.e. macro particles or structural defects). The observed frac-ture behaviour is further associated with large-scale dynamic-mechanical analysis of coated Ti6Al4V platelets to consider stress fields induced by the coating-substrate interface. The results are expected to provide key-insights into the underlying mechanisms promoting crack growth in PVD coated speci-mens combining the world of micro- and macro scale testing methods.

Part II: Ternary transition metal diborides: A new generation of protective coating materials?

Future high-performance components used in aviation or energy production require customized protective coating materials to fulfil specific criteria on efficiency as well as durability. Next to well-established nitride-based coatings are boron containing systems an upcoming and highly promising coating class. Here, ternary transition metal diborides are relatively unexplored compared to their bi-nary counterparts such as hard and inelastic TiB2. Typically, these hard ceramic based coatings fail due to their extremely limited capability for plastic deformation as well as a pronounced formation of vol-atile (boron based) oxides. Within this seminar, I want to discuss these specific challenges for different binary and ternary model systems exhibiting outstanding material properties, i.e. long-term oxidation resistance at 1200 °C or a fracture toughness above 4.8 MPa·m1/2, while maintaining super hardness. To systematically describe various aspects in the design and syntheses of non-reactively sputter de-posited boride-based coating materials, a broad set of high-resolution techniques (i.e. HR-TEM, APT, ERDA, or micro-mechanical testing) but also atomistic modelling (DFT using VASP) is applied.